Now you are at United States.

Any change of position while the purchase will cause the items to be removed from the shopping cart.

Click here to see the list of available countries.

For Campagnolo, the SHAMAL family has always represented an evolutionary impulse beyond its own limitations, a challenge and a triumph. Since 1992, this wheel has been an icon for enthusiasts, who with SHAMAL saw the birth of the high-profile concept, a forerunner of what is currently available on the market. SHAMAL still has the same meaning for Campagnolo: breaking the mould to face the future.

The first Campagnolo wheel dedicated to endurance was born in keeping with this mantra, with a 21 mm internal channel that can accommodate larger tyres and ensure the cyclist maximum comfort on races and long rides. This new product was intended for a broader customer base, with a new, more accessible price point, but with every feature necessary to guarantee the maximum performance and style that characterise Campagnolo wheels. Carbon rim with unidirectional finish and a differentiated front/rear profile, modern rounded profile, new aluminium hubs, cup-and-cone bearing system. Every design decision is determined by the sole goal of improving cyclists’ performance over long hours on the saddle, providing comfort and rideability in all conditions.

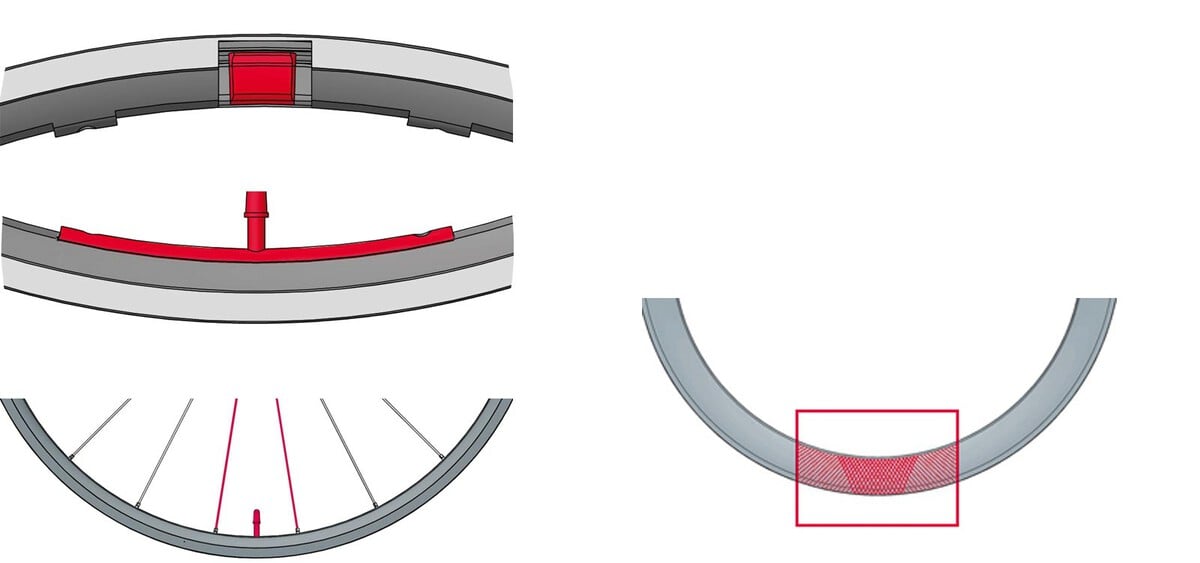

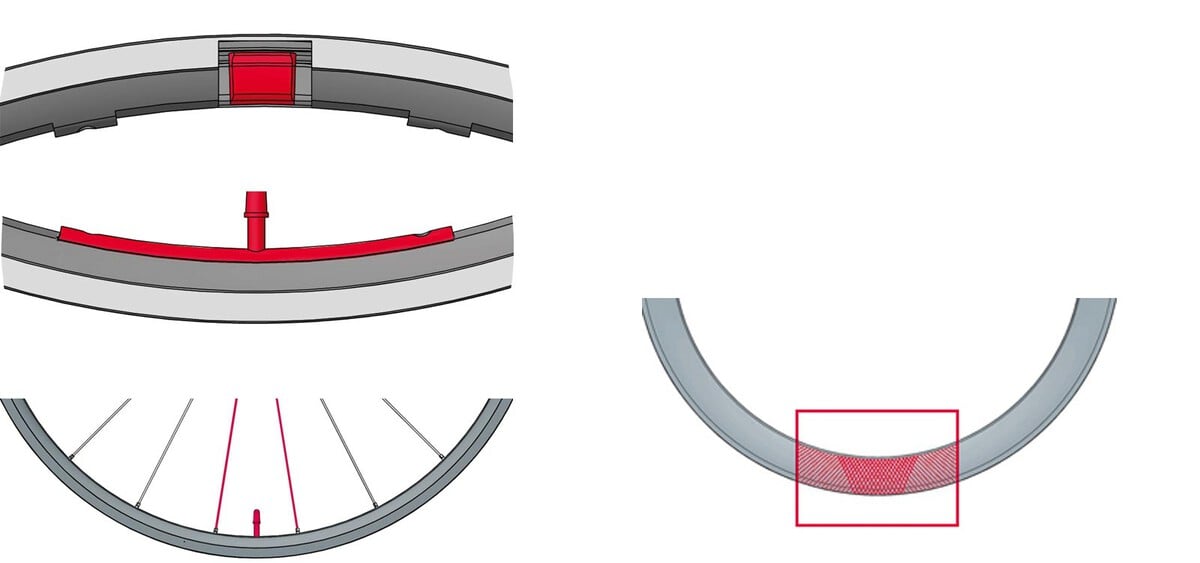

The profile of the rim, which has an internal diameter of 21 mm, makes for perfect pairing with 25, 28 and 30 mm tyres. The wide channel, however, makes this wheel a complete all-rounder, also suitable for larger tyres that are perfect for gravel biking. Thanks to 2-Way Fit technology, Campagnolo guarantees complete compatibility with both clincher and tubeless tyres. The hole-free upper bridge, achieved through the patented MoMag system, allows a weight saving, increased rigidity and now also an aid to using tubeless tyres: no tape is required for the seal. Maintaining and cleaning the wheel on tyre changes has never been easier. These wheels are designed to ensure extreme performance, comfort and versatility for cyclists.

Campagnolo has always been a byword for reliability: the G3 spoking system with double spokes on the left of the front wheel ensures balanced and safe braking in all conditions. The construction of the whole wheel, engineered by considering every single component as part of a system, makes each Campagnolo product a godsend on longer rides, cyclosportives and the most demanding adventures.

SHAMAL CARBON DB: a renewed icon that maintains its blazing, indefatigable soul, like the wind from which it takes its name.

Available versions: dark label, Campagnolo N3W™, Shimano HG, Sram XDR™ FW hub.

C21, 21 MM INTERNAL CHANNEL

The rim design allows the utmost versatility in tyre use, from the most comfortable for road use (25, 28, 30 mm) to the largest for cyclo-cross and gravel use (starting from 32 mm and going up to the largest, 45/50 mm).

Thanks to the patented MoMag system and the upper bridge with no holes, SHAMAL is ready for use with tubeless tyres but without requiring tape for the seal. Easy maintenance and cleaning guaranteed.

The 2-Way Fit profile allows both clincher and tubeless tyres to be fitted. This makes SHAMAL the ideal wheel for all road riders (traditionalists and innovators), but also for all gravel riders who use tubeless tyres without abandoning the option of fitting an inner tube in case of major punctures, a lifesaver far from home.

DIFFERENTIATED PROFILE, FRONT 35 MM / REAR 40 MM

SHAMAL is engineered to ensure the utmost comfort on longer rides, both in terms of bumps and ease of riding, without ever sacrificing performance.

40 mm at the rear to guarantee maximum responsiveness and complete power transfer.

35 mm at the front ensure the best possible rideability, in all conditions.

CAMPAGNOLO'S UNIQUE STYLE, TECHNOLOGY AND ELEGANCE. FINALLY ACCESSIBLE

The first Campagnolo-branded carbon wheel at a new price point, with the aim of sharing Campagnolo’s technical advantage with a broader customer base.

The first Campagnolo wheel in the endurance segment: performance combined with unprecedented comfort - The well-known cup-and-cone bearing system guarantees unique smoothness which, combined with the possibility of adjusting the play, positions the Campagnolo system at a higher level than standard bearings in terms of both performance and durability (option to purchase Campagnolo USB and CULT ceramic systems separately).

The unidirectional, unpainted carbon rim allows a weight saving, dropping the wheelset weight to 1585 g and making SHAMAL CARBON a complete all-rounder.

- 1.585 g

- 24 steel spokes in the front elliptical aero cross section, spaced in groups of three through the G3 system

- 24 steel spokes in the rear elliptical aero cross section, spaced in groups of three through the G3 system

- Black aluminium monolithic hub

- USB cup-and-cone bearing system

- Hub edge: 100 mm in the front, 142 mm in the rear

- Axle type: 12mm aluminium thru axle

- Cup-and-cone bearing system

- Clincher

- Tubeless

- Profile height: 35 mm front / 40 mm rear

- Rim material: carbon

- Rim cross section (H x W): 35-40/28.1 mm

- Internal diameter of rim: 21 mm

- Adhesive Stickers graphics

- The SHAMAL CARBON™ Disc Brake wheel is entirely hand-assembled by a specialised Campagnolo® technician and is 100% checked by electronic instrumentation. This procedure ensures that every single Campagnolo® wheel offers maximum performance and reliability

- 50 mm tubeless valve

- Bushing to reduce the size of the valve hole

- 2 levers in composite material for tyre removal

- User manual

- N3W™ adapter kit driver body for 11-12s compatibility (Campagnolo N3W™ body version)

- Removal and refitting wheel front hub (cup-cone bearings)

- Replacement of free wheel body pawls

- Removal and refitting body free wheel

- Table of technical manuals of the wheels

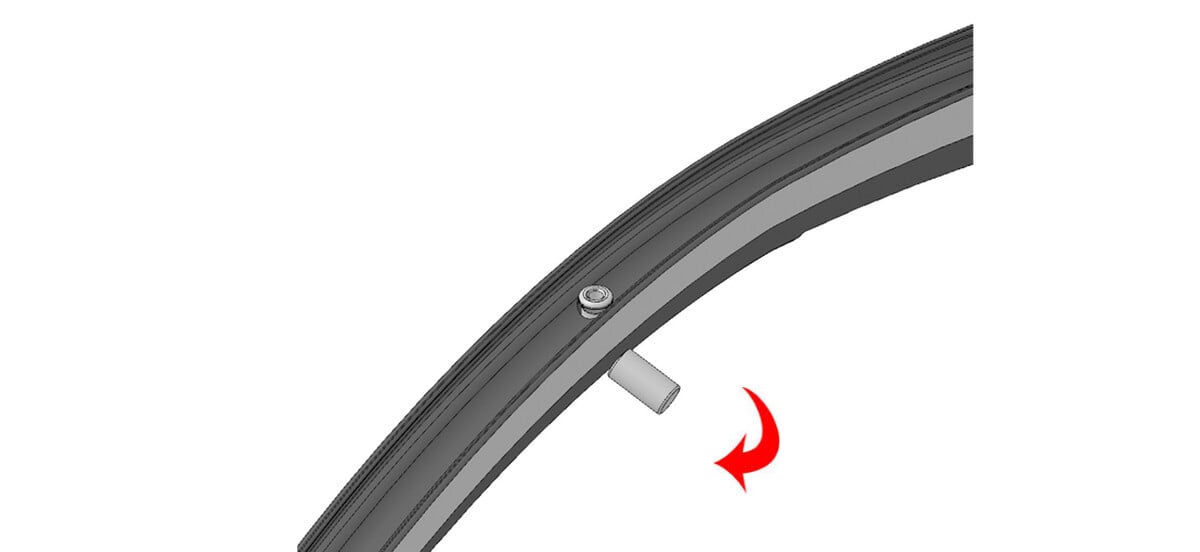

- Replacement of the spoke with Momag system - open spoke seat on the hub

- Removal and refitting wheel front hub (cup-cone bearings)

- Removal and refitting wheel rear hub (cup-cone bearings)

- Removing front wheel adapters

- Wheel centering

2-WAY FIT™

2-WAY FIT™ is the innovative profile that lets you fit either a tubeless tire or a classic clincher.

DYNAMIC BALANCE™

The concept is as simple as it is genius: balancing the weight of the rim joint with a mass of identical weight on the opposite side of the rim.

G3 SPOKE GEOMETRY

Campagnolo’s iconic G3 geometry challenges the conventional configuration of wheel spokes on racing bikes. Groups of three parallel straight-pull spokes are in fact arranged in a ratio of 2:1.

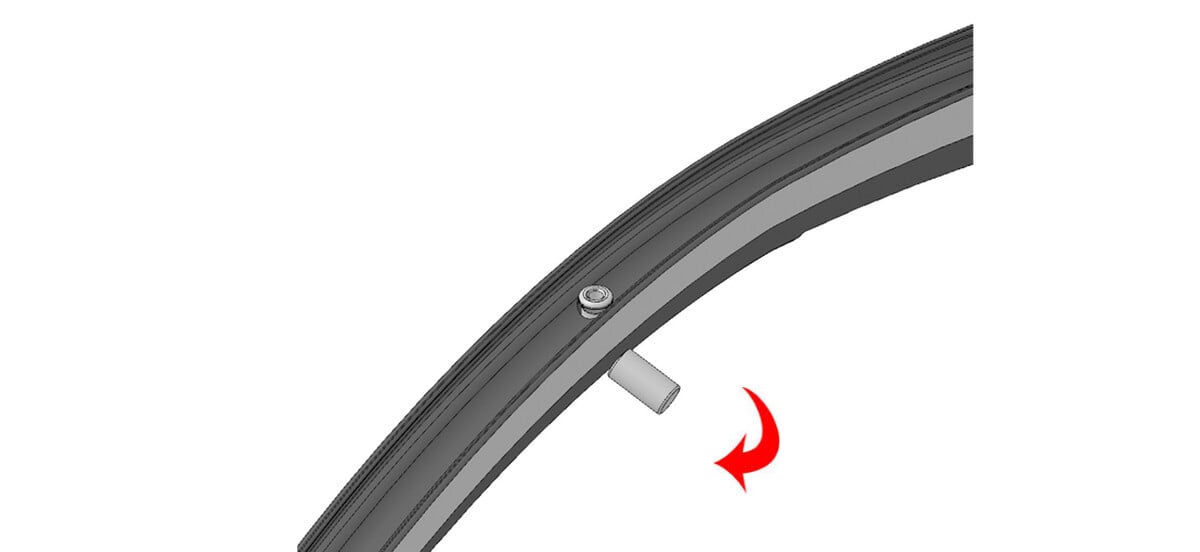

MOMAG™

An absolute genius of a magnet. It is the tried and tested, patented “Mounting Magnet” system: MoMag™ for short.

N3W

N3W stand for NEXT 3 WAYS, a patented standard for a freewheel body engineered to house 11-, 12- and 13-speed cassettes with 9-, 10- and 11-tooth starting sprockets that is still compatible with older 9- and 10-speed cassettes.

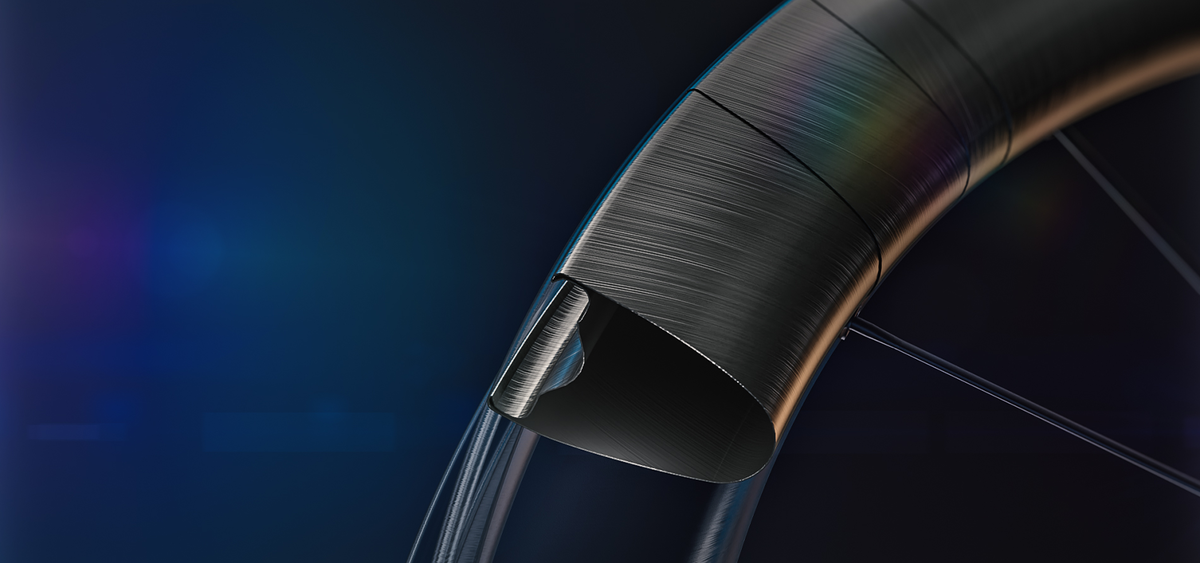

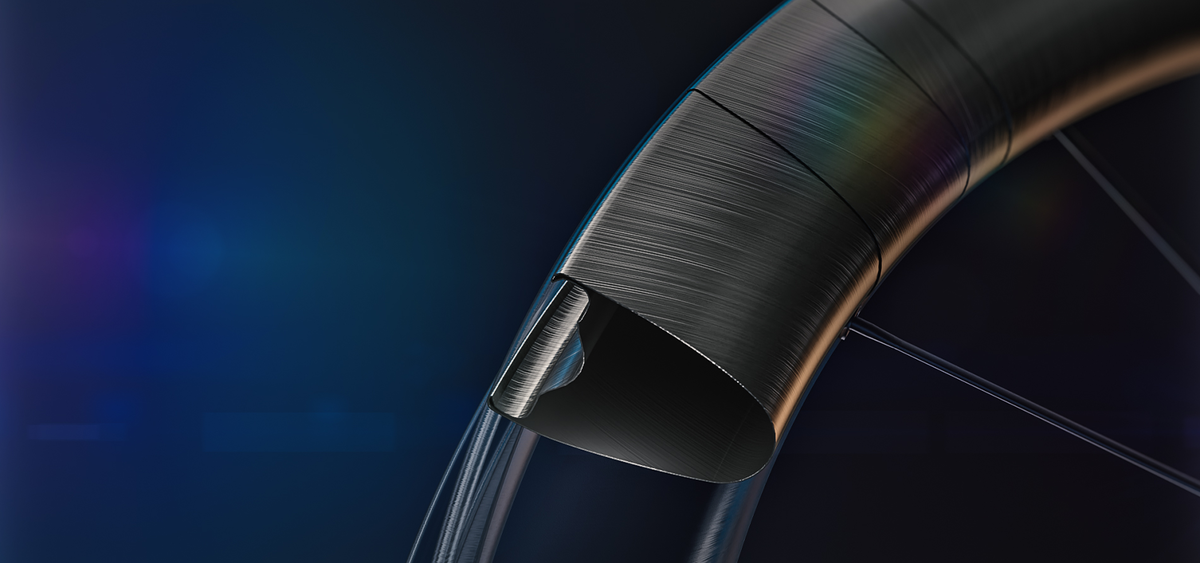

SINGLE-JOINT CONSTRUCTION

The special lamination process designed to produce a rim with just one joint in the fiber: a lightweight resistant carbon monolith.

Thanks to 2-Way Fit™ technology, if you choose Campagnolo® wheels you can test them out to see which of the two solutions feels better for you, or use clinchers for training and tubeless for racing. Tubeless are without doubt the future of tires for road cycling. Apart from greater comfort, other big advantages include the fact that tubeless tires let you make the most of the greater smoothness due to the absence of friction between tire and inner tube. Plus, a tubeless will not suddenly deflate when punctured, which is definitely a good thing in terms of safety. And finally, tubeless tires do away with any risk of pinch flats, because there is no inner tube. If you get a puncture with a tubeless tire, the Campagnolo® 2-Way Fit™ system lets you simply remove the airtight valve, fit a classic inner tube and continue to pedal: problem solved.

RIM Dynamic Balance™ – aluminum wheels The concept is as simple as it is genius: balancing the weight of the rim joint with a mass of identical weight on the opposite side of the rim. For top-end models this is achieved by intervening on the section of the rim opposite the joint. SPOKES Dynamic Balance™ For entry-level models, the balance is achieved with two oversized spokes in the section opposite the joint. The result is a wheel with perfectly balanced rotational dynamics. RIM Dynamic Balance™ – Carbon wheels For carbon wheels, the principle is the same but the technology differs. The pieces of carbon cloth are aligned using a special procedure that ensures the rim is always balanced.

Campagnolo’s iconic G3 geometry challenges the conventional configuration of wheel spokes on racing bikes. Groups of three parallel straight-pull spokes are in fact arranged in a ratio of 2:1. Having twice as many spokes on one side allows wheels with G3 technology to achieve perfectly balanced tensions, increasing stiffness and improving energy transfer. An iconic design with unique style that helps to improve load absorption and reduce weights. The G3 spoke pattern also has a positive effect on the steering experience: the original triplet pattern reduces perceived vibrations, minimizing micro-deformation of the rim under tension and its response to stressors on the course. G3 geometry is designed with optimized solutions for front and back wheels. The front one has more spokes on the disc side to absorb braking loads. Whereas on the back one the same loads are transferred to twice the number of spokes on the cassette side through the monolithic hub body: an intuitive idea that enables functioning during both braking and energy transfer during pedaling. The G3 spoke pattern is used on Bora WTO and Bora Ultra WTO racing wheels, wheels in the Shamal family and on all the aluminum wheels in the Campagnolo collection.

WHAT IS THE MOMAG™? An absolute genius of a magnet. It is the tried and tested, patented “Mounting Magnet” system: MoMag™ for short. HOW DOES IT WORK? The nipples, once inserted inside the rim via the valve hole, are “guided” to the point of connection with the spoke by means of a magnet. This simple but ingenious system makes it possible to have a wheel without holes on the upper bridge, but with spokes tensioned by traditional nipples. ADVANTAGES No holes on the rim means that the rim is uniform at every point, free from stress points or zones of structural weakness. It offers a further advantage in terms of lightness for clincher profiles as no rim tape is required. The advantages are immediately clear: greater rim lifetime, greater resistance to fatigue, the possibility to give the spokes greater tension and greater stiffness, which, in terms of performance, mean better reactivity and ease of handling. But that’s not all. The advantages also include extremely quick simple spoke maintenance or replacement. MOMAG™ technology is used on Bora WTO carbon wheels for racing bikes and on Shamal Carbon, Levante and Hyperon Ultra wheels.

N3W stand for NEXT 3 WAYS, a patented standard for a freewheel body engineered to house 11-, 12- and 13-speed cassettes with 9-, 10- and 11-tooth starting sprockets that is still compatible with older 9- and 10-speed cassettes. To make it compatible with all of today’s cassettes with 11-tooth starting sprockets, simply use the N3W ring (kit complete with ring + ring code AC21-N3W), which makes them the same length as the classic body. N3W is directly compatible with the new Campagnolo cassettes with 9- and 10-tooth starting sprockets. N3W has the same groove profile as the classic Campagnolo body but it is 4.4 mm shorter, making it much lighter. There is also a N3W Light version with an aeronautical-quality aluminum hub with optimized geometrics that delivers maximum torsional stiffness and maximum performance control. Special Campagnolo processes have resulted in a patented Next 3 Ways freewheel body with unmatched smoothness and lightness. The N3W freewheel body is used on Bora WTO, Bora Ultra WTO, and Hyperon Ultra carbon wheels for racing bikes and on Shamal Carbon wheels.

For construction of its carbon fiber wheels, Campagnolo uses a special lamination process designed to produce a rim with just one joint in the fiber: a lightweight resistant carbon monolith. This particular technology is totally different to the industry standard four-joint constructions. The resulting rim is extremely stiff and responds immediately to the terrain, transmitting pedal power and efficiency to the ground. A construction excellence introduced with Hyperon Ultra carbon wheels that makes the rim incredibly easy to handle, hardwearing and resistant to damage. A construction excellence used on Bora Ultra WTO, Hyperon Ultra, Shamal, and Ghibli wheels for racing bikes and on Levante gravel wheels.